YEARS OF EXPERIENCE

in Manufacturing Wheel Fasteners

With more than 40 years of experience in manufacturing wheel fasteners,

TPi has become the expert in forging wheel fasteners.

Quality Assured

We are devoted to making products that meet the highest standards of safety, durability, and insist on producing all our fasteners in Taiwan as to be able to supervise and control each stage of production, assuring our consistent quality.

Our CertificationsTAF-iLac Certified Laboratory

Gourmet Equipment (Taiwan) Corporation, TPi’s parent company, owns in house laboratory and the laboratory has been certified by TAF-iLac in 2016. This proves the laboratory conforms to the general requirements for the competence to carry out tests and/or calibration required by International Standard Organization, and also ensures the laboratory gets the same verification capability as SGS. This manifests TPi’s permanent promise for our customers-persistent improvement and stable quality on our products. Please refer to the certificate below to see our accredited scope.

TAF CertificateDevelopment And Quality

We have a complete and successful Quality Management System (QMS) that is IATF 16949 certified by TUV Rheinland. We have our in-house laboratory checking parts at different stages of production. All TPi conducts tests on durability, torque, fatigue test, torque retention, and chemical composition analysis. TPi is proud to offer our Quality Check Report to our customers.

10 Million Insurance Coverage

TPi is the ONLY wheel fastener manufacturer who issues products insurance of USD 10,000,000 for our customers. No one does that, but TPi does.

CertificateChemical Analysis Equipment

Mechanical Tester

- Universal Torque Testing Machine

- Torque Wrench

- Automatic Hardness Tester

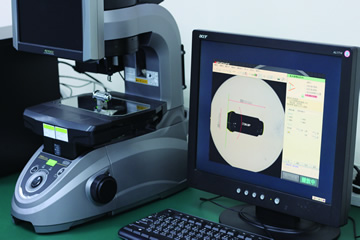

Dimensional Measure Instrutment

- Head Thickness Gauge

- Profile Projector

- Punch Gauge

- Digital Height Gauge

- Caliper

- Micrometer

- 2.5D - Image Processing Measuring Instrument

- Coordinate Measuring Machine

- Gauge Block

- Ring Gauge

- Plug Gauge

Other Performance Tester

- Salt Spray Testing Machine

- Bolt Torsion Testing Machine

- X-ray Coating Thickness Measurement

- Microscope

- Pendulum Impact Tester

- Cutting machine

- Electrical Conductivity Meter

Operation Process

Material Analysis

TAF-ILAC certified laboratory for material inspection and functional properties test.

Cold Forging

Forging Capability (mm): 100L x 32 Dia., 60L x 34Dia.

Threading

Speed efficient and accurate auto-threading system.

Welding

Cost-effective lug nut production method, finest technology, maintaining great look.

Heat Treatment

Carbonized or straight-treatment, to achieve required hardness.

Tumbling

Polish and smoothen product’s surface, preparing parts for plating.

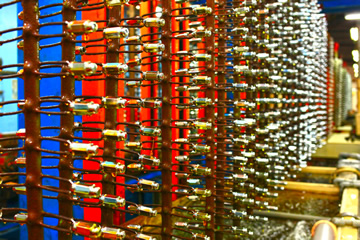

Plating

Advanced triple nickel/ chrome plating or zinc plating technology for even and corrosion-resistant coating.

Quality Control

High precision specification measurement check, chemical composition analysis, and physical properties check.

Warehousing

Efficient & spacious automatic retrieval and storage system.

Optical Sorting

In-house designed optical sorting machine to do 100% lock pattern & thread size identification.

Auto-packaging

Automatic packaging facility to do customized package.

Shipping

Store all the consignment in our warehouse and retrieve the good with care and make the shipment.